Bring Your Vision to Life with 3D Rendering to Reality

Tuesday , 18 October 2022 | design, C2 Imaging, production, general printing, creative services

What is rendering to reality?

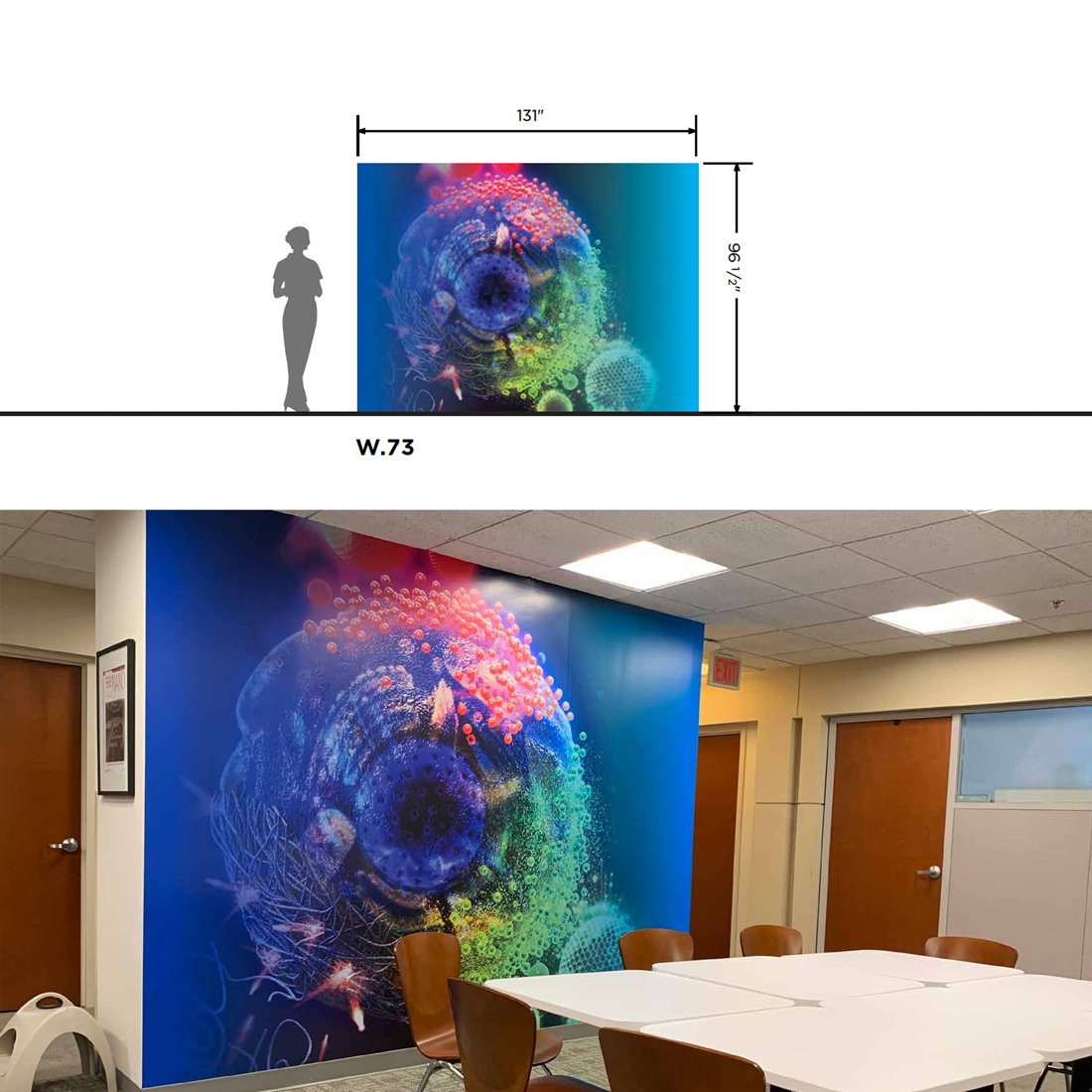

You may have heard the term “rendering to reality” and wondered what it meant. It refers to the process of creating a 3D rendering, a three-dimensional and realistic model of something using computer software, prior to production.

You might not know it, but 3D renderings are used all the time. Every project presents a unique set of challenges requiring innovation to bring it to life. With 3D rendering, you can create a lifelike representation of your desired product right from drawings, sketches, or photographs including specifications that make it realistic and functional.

A 3D rendering might start from a simple sketch scratched onto a napkin over a coffee meeting. Or the idea might come from a client that already has a concept in mind. No matter the scale or scope of your design, C2 Imaging provides creative services tailored to your project’s needs.

How is 3D rendering used?

A 3D rendering can be used as a photorealistic image to show all the details, materials, dimensions, and colors to make it functional in real life before committing to production or prototyping.

Because you don’t have to produce a new prototype for every design change, the structural designer can try out different ideas to find the perfect solution. This allows the designer to present different variations and see it in a variety of environments, or even in 360 degrees to see every angle. This helps the team understand how the product will function in real life.

What is C2’s process?

- Insight & Discovery

You can bring us a simple sketch to start with, or we can design one for you. We use industry research and planning to bring you the best possible idea during concepting. Plus, with our years of experience, we can make anything come to life.

- Creation

We make sure that what we design, we can build. We consider incorporating new materials and technology while creating a design that solves your challenges.

“We pride ourselves on the fact that whatever we design can be built…easily and affordably within our clients’ budgets. At the outset of any project, we think in terms of how something can be developed as a system of multiple components or as an individual component. We also understand fabrication and materials.” –C2 Imaging

After the design stage, we prototype, deciding on an array of surfaces and substrates. Each product or structure is rigorously prototyped and tested in-house.

- Execution

With our broad network capabilities, we can print just about everything, making your 2D drawing a reality. We can kit the product, produce supplementary items like counter cards, backlit graphics, and signage. Or we can ship it partially assembled for an easy on-site setup including personalized assembly instructions. Then we install it through our nation-wide installation network.

What are the benefits?

- Time

By rendering the item in computer software first and smoothing out all the details, you save time on making prototypes with each concept change as it develops. This saves weeks or months needed to develop a prototype.

- Money

With a reduction in prototyping, you save on materials, transportation, staff, and other expenses. Designers can make changes right in the 3D model to see whether the changes work or not instead of printing out more and more samples.

- Effort

By designing digitally on the front end, modeling avoids errors before it goes into production. A 3D rendering will accurately show the product’s specifications to reduce time spent on many adjustments during development.

Anything is possible

See 3D rendering create anything from interactive displays connected to phone apps and tradeshow booths to in-store promotional signage. Contact us to get started with your idea- even if it’s just a scribble on a napkin!

Oct 18, 2022 |

Topics: design, C2 Imaging, production, general printing, creative services